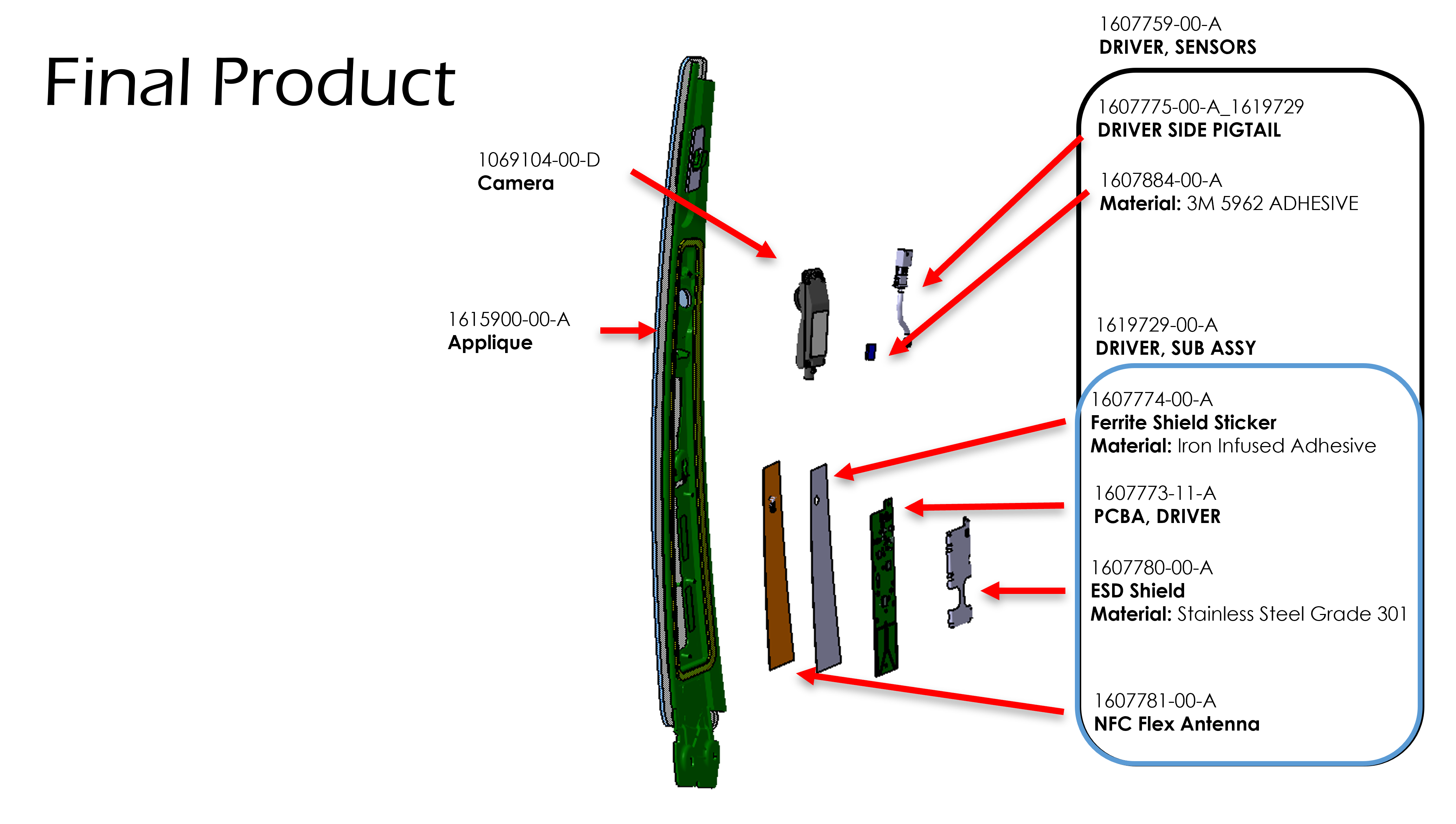

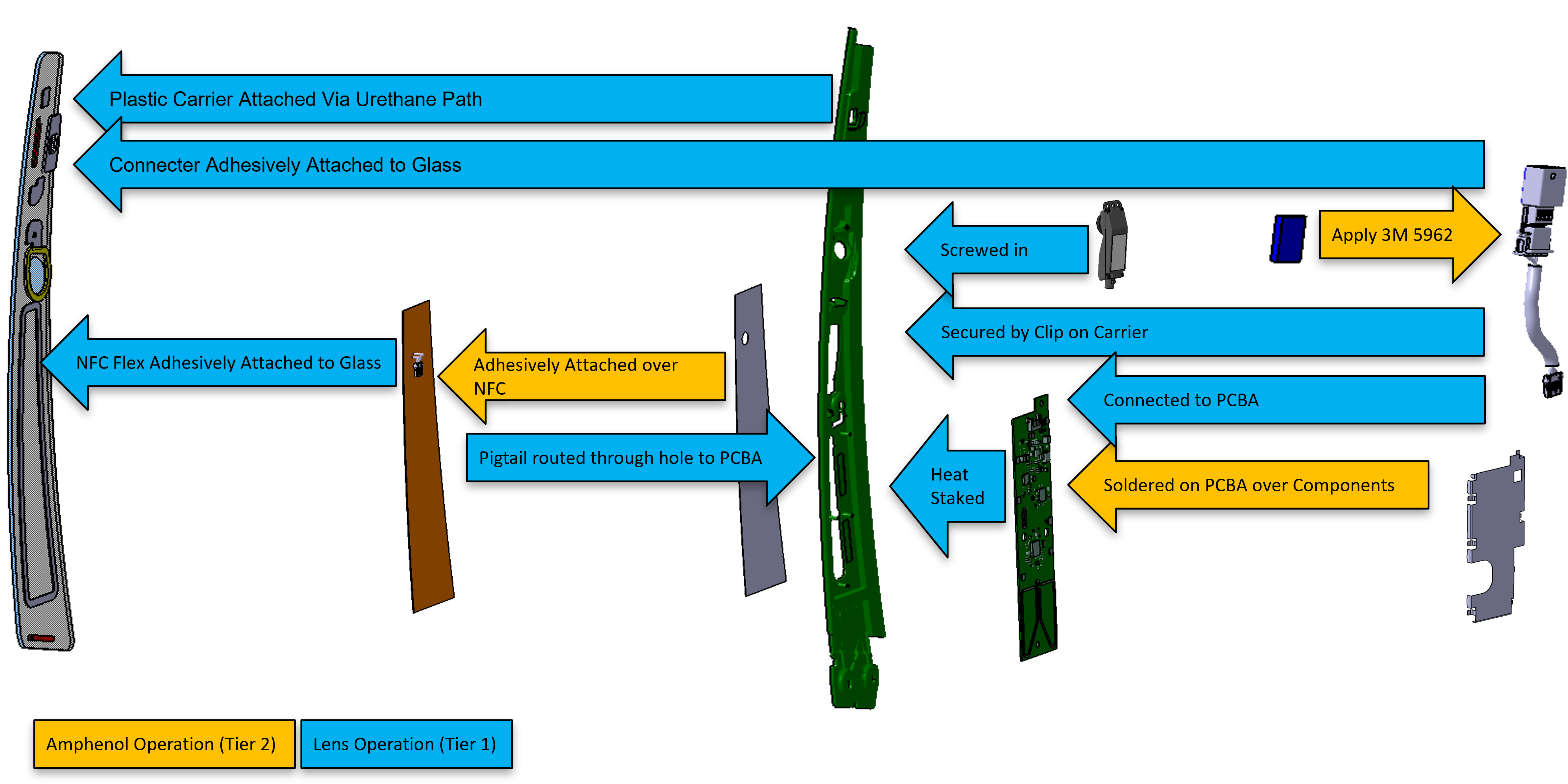

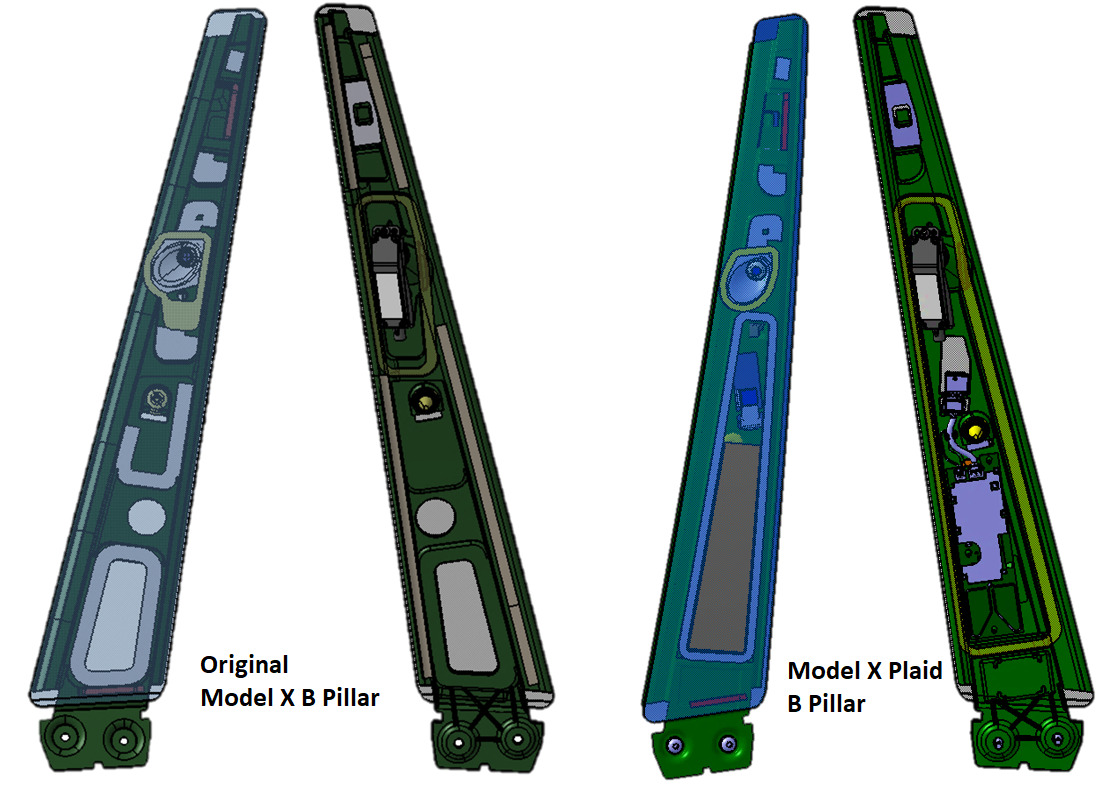

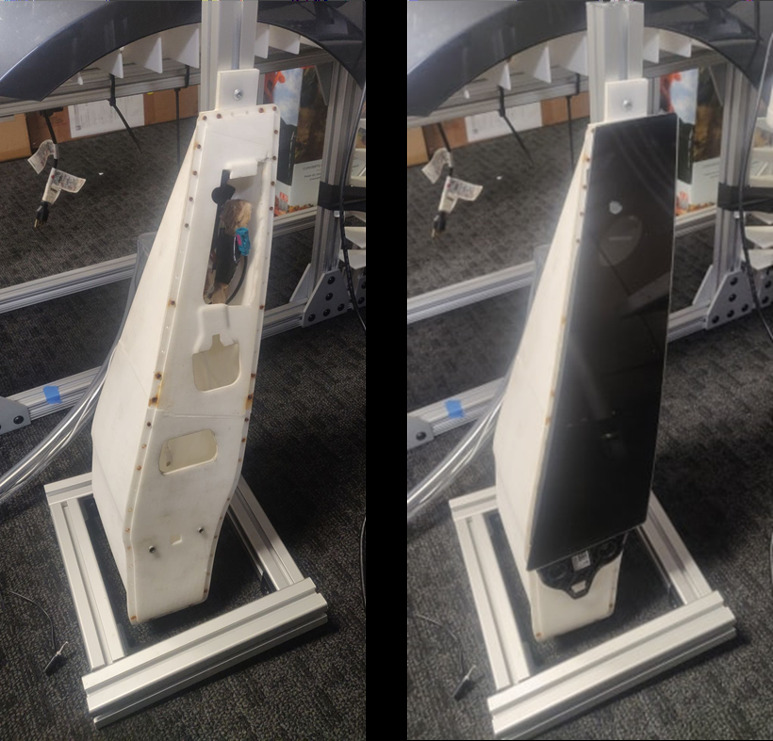

Tesla: Model X B-Pillar

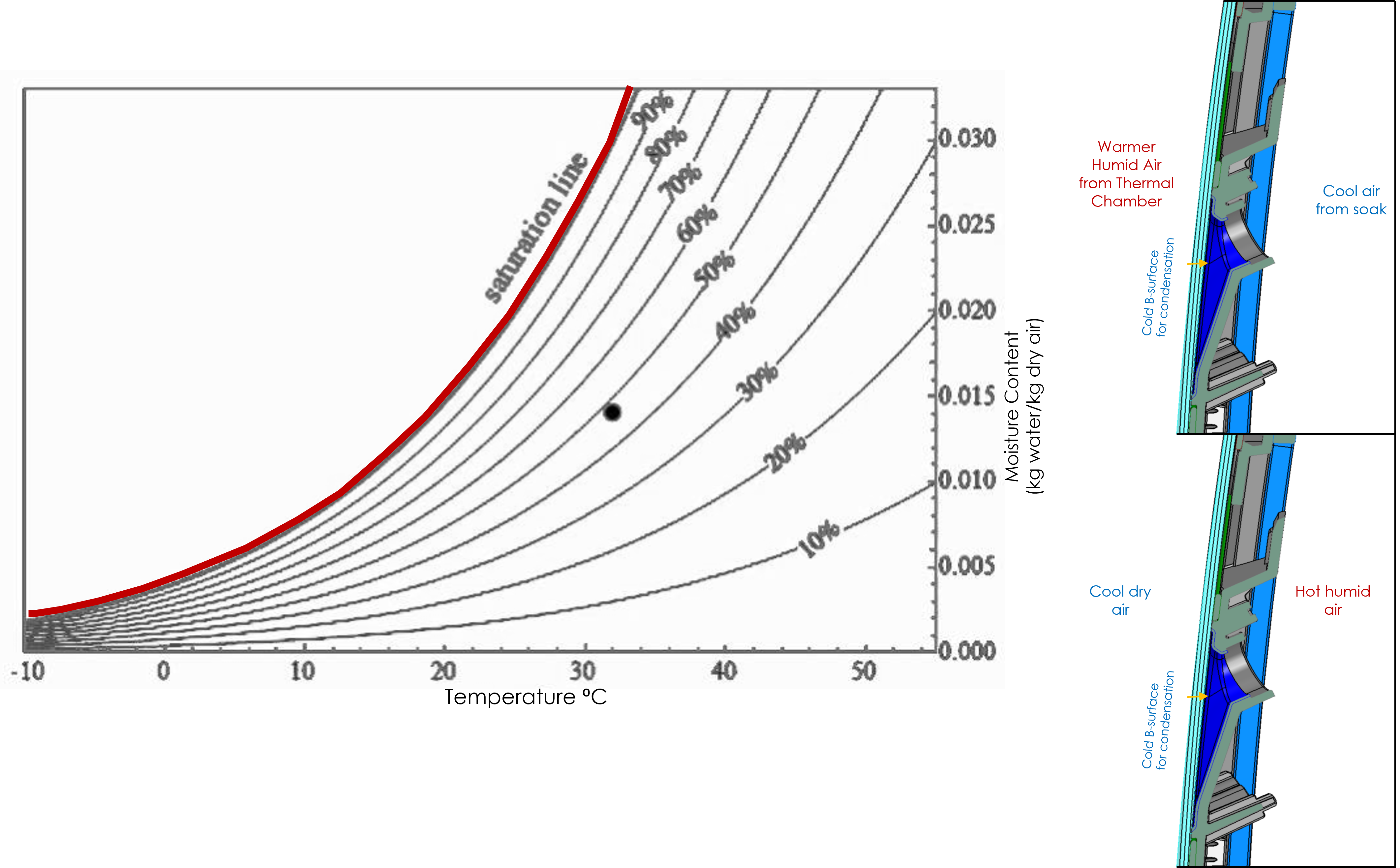

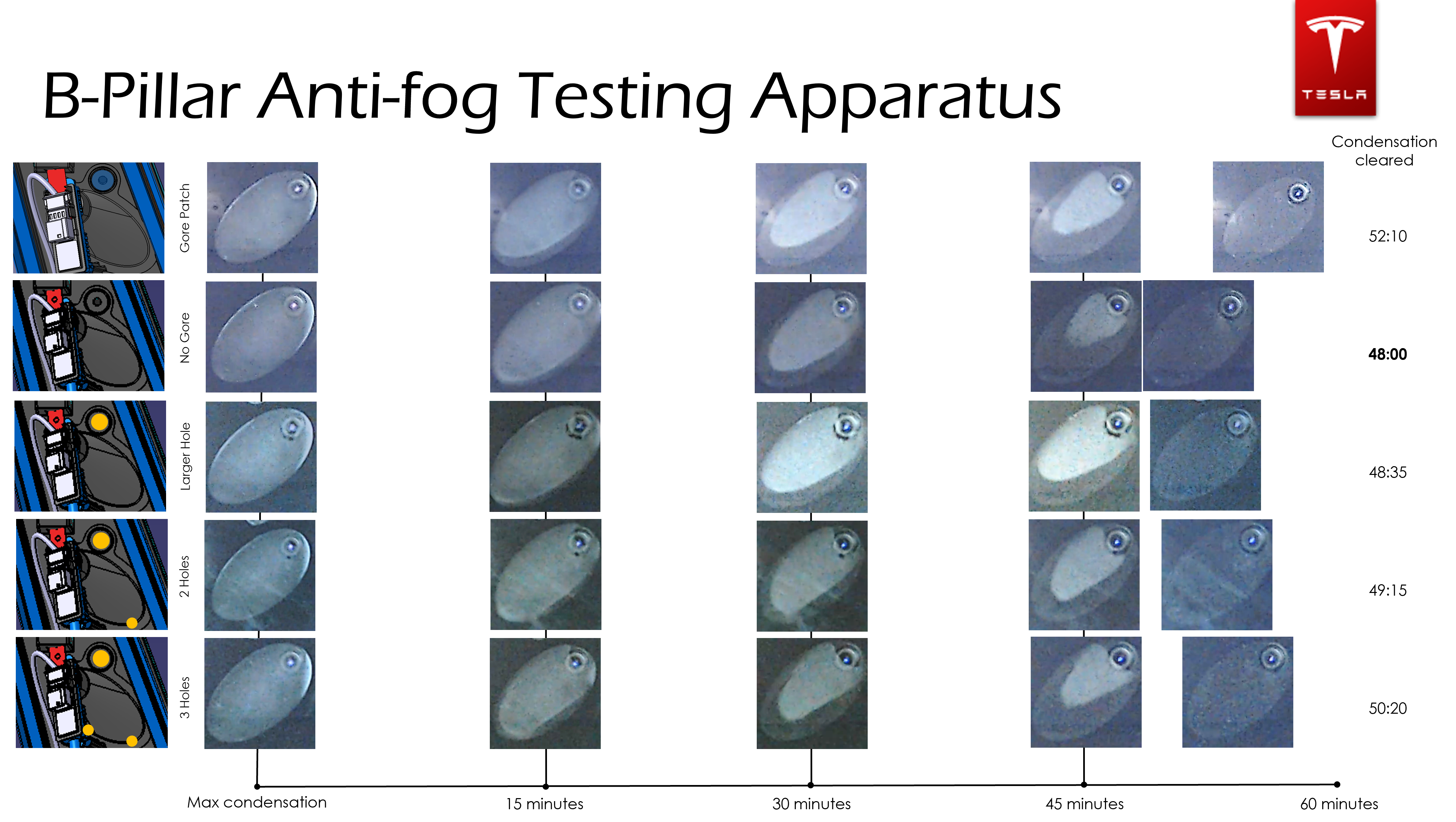

Complex Electro-Mechanical Design, Assembly, and Testing

- Strengths demonstrated: Electro-Mechanical Design, Design for Assembly, Design for Manufacturing, Tolerance Analysis, Design of Experiments, Project Requirements Definition

- Tools used: CATIA, 3D Printer, Thermal Chambers

- Company Team: Tesla Autopilot and Electronics Product Design Team

- Project date: 2020