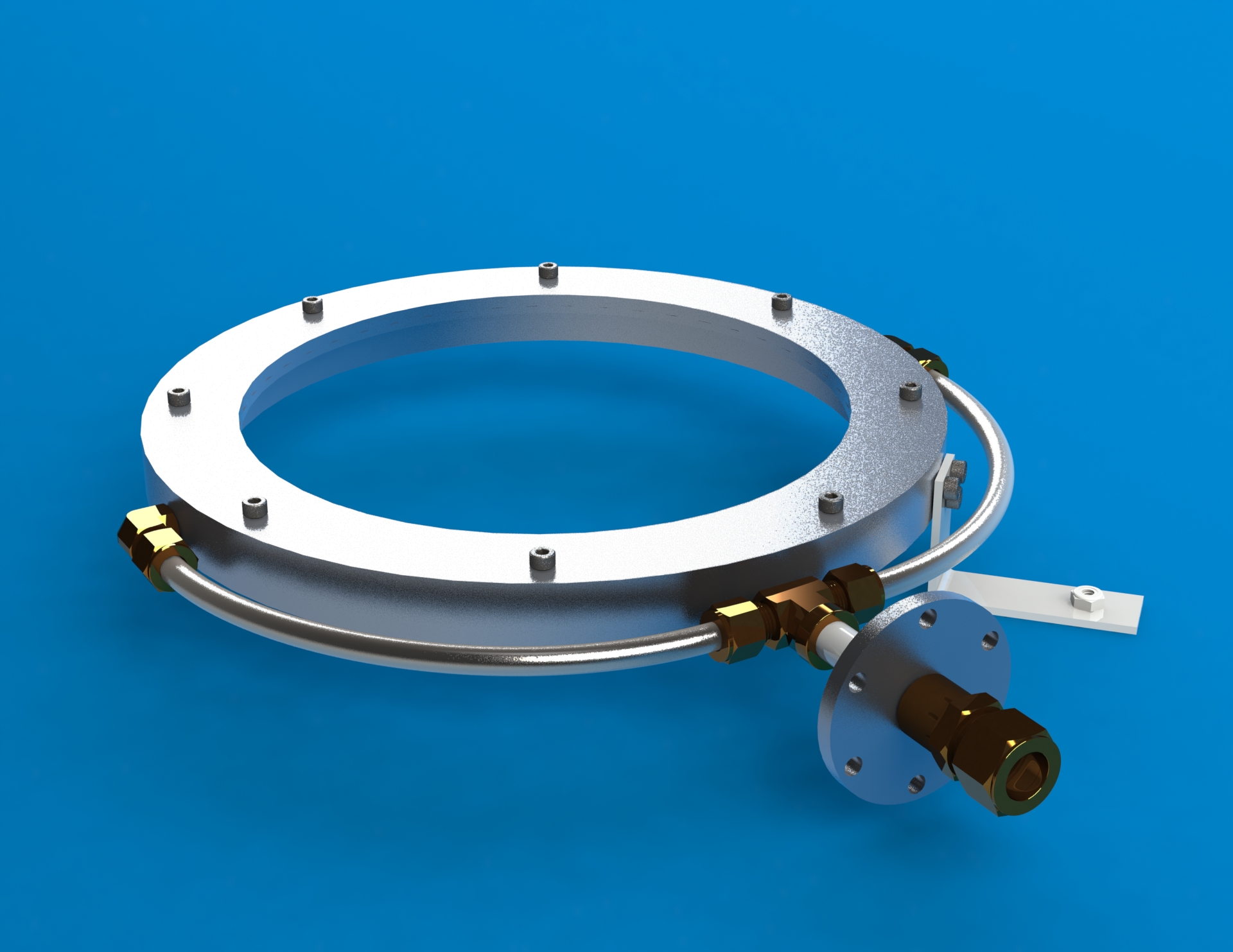

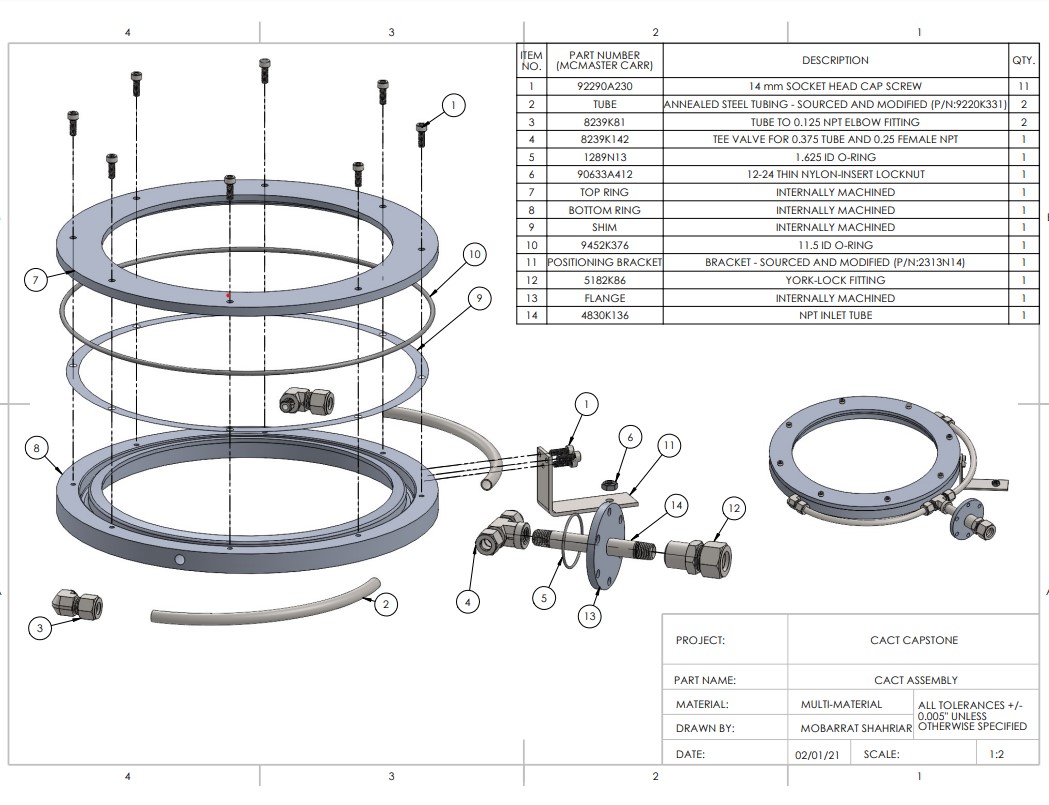

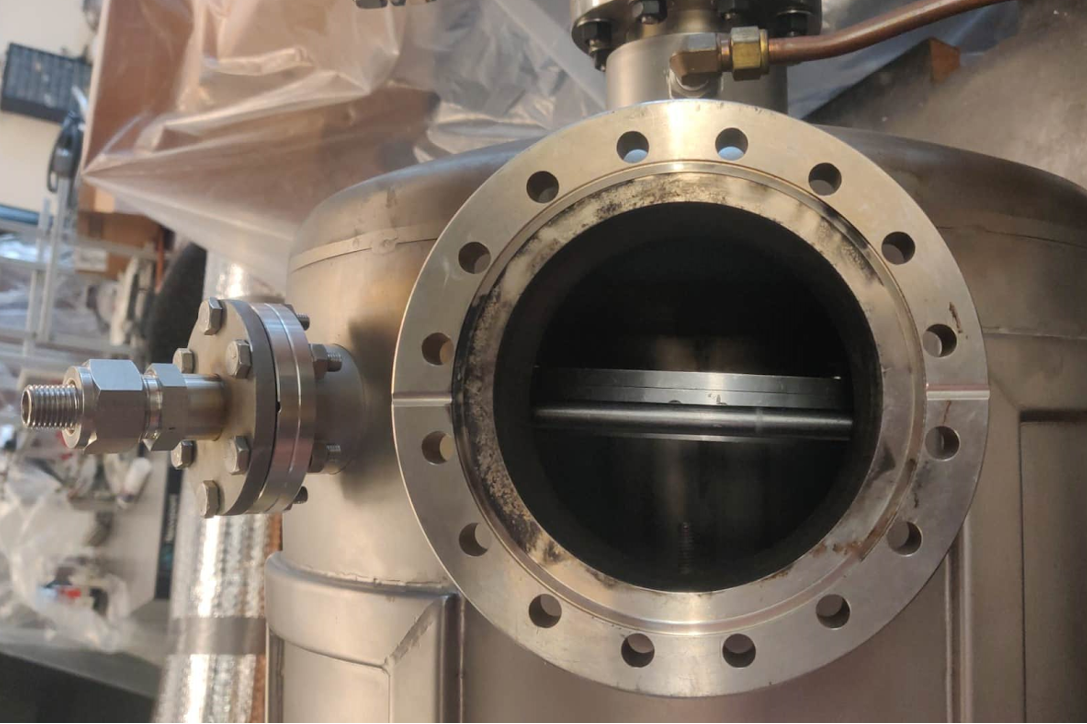

Metal Powder Cooling Shroud

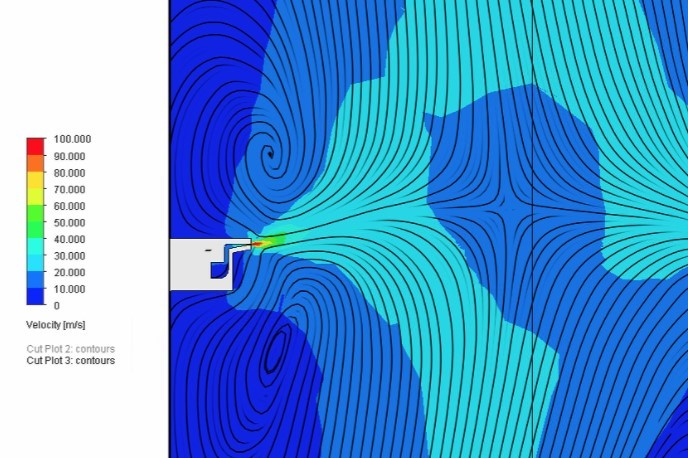

Defining Project Requirements, 3D Design & Analysis, Procurement, and Testing

- Strengths demonstrated: Mechanical design, design for manufacturing, FEA Simulations, CFD

- Tools used: SolidWorks, Ansys

- School Team: University of Toronto CACT Laboratory

- Project date: 2020 - 2021