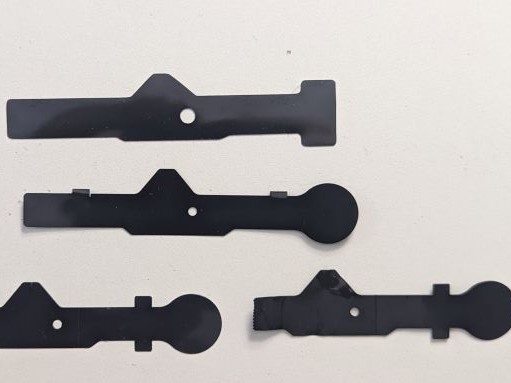

Tesla: Model X Keyfob

Cost-Saving Process Improvement

- Strengths demonstrated: Design of Experiment, Mechanical Design, Iterative Design, Testing, Process Improvement

- Tools used: CATIA, Soldering, Multimeter

- Company Team: Tesla Autopilot and Electronics Product Design Team

- Project date: 2020

.gif)